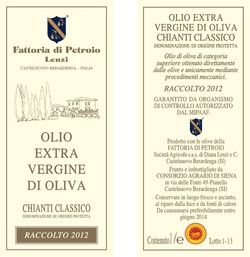

Extre Vergin Olive Oil DOP Chianti Classico 2012

Highest quality, certified Olive Oil produced from olives harvested from the 780 olive trees on the Estate of Fattoria di Petroio.

Location: Fattoria di Petroio-Quercegrossa (SI)

Number of plants: 780

Altitude: 380 meters above sea level

Soil composition: Medium blend of clay & limestone with a rich texture

Cultivar or varieties: Leccino, Moraiolo and Frantoio

.

Harvest Method: Hand picked (browsing) harvested between November & December.

Pressing and extraction: Continous Cycle Method of Milling with cold extraction.

Yield: 11,7%

Quantity of oil produced in 2012: 560 liters

Storage: In stainless steel tanks

Acidity: 0,17 (% of oleic acid)

Number of peroxides: 5,74 (meqO2/kg)

Organoleptic exam: Color: intense dense green. Aroma: pleasing & fruity. Taste: nicely balanced with spicy notes. Perfect for coking but special when used for dressing both cooked and raw foods.

Location: Fattoria di Petroio-Quercegrossa (SI)

Number of plants: 780

Altitude: 380 meters above sea level

Soil composition: Medium blend of clay & limestone with a rich texture

Cultivar or varieties: Leccino, Moraiolo and Frantoio

.

Harvest Method: Hand picked (browsing) harvested between November & December.

Pressing and extraction: Continous Cycle Method of Milling with cold extraction.

Yield: 11,7%

Quantity of oil produced in 2012: 560 liters

Storage: In stainless steel tanks

Acidity: 0,17 (% of oleic acid)

Number of peroxides: 5,74 (meqO2/kg)

Organoleptic exam: Color: intense dense green. Aroma: pleasing & fruity. Taste: nicely balanced with spicy notes. Perfect for coking but special when used for dressing both cooked and raw foods.

EXTRA VERGINE OLIVE OIL: FROM OLIVE TREE TO OLIVE OIL

HARVEST:

The time when the olives are harvested depends on three elements: variety of Olive drupe or Cultivar, Altitude and Weather.

Cultivars: Frantoio, 60% Correggiolo 10% Moraiolo 10% Leccino 20%

Altitude: 360 s.l.m.

Weather: the olives are generally picked between the 15th of November and the 15th of December. When the invaiatura or the color of the olives changes from green to violet or brown it is time to get ready for the harvest.

The olives are hand picked by brucatura or browsing and pulled off the branch by a harvesting hand. They are stored in small plastic crates in a cool dry place and taken to the Frantoio or Olive Oil Mill within 3 days of harvest.

Olive Oil from Fattoria di Petroio is milled at the Frantoio di Pianella in Castelnuovo Berardenga Siena.

t comes exclusively from the 860 trees on the Property of Fattoria di Petroio, Quercegrossa, Siena

Frantoio di Pianella uses the Continous Cycle Method of Milling.

There are Five Cycles or Phases during the Milling Process

Phase 1

The olives are received and weighed.

Excess leaves are removed and the olives are lightly rinsed to take away any foreign, extraneous matter.

The olives are poured gently into receiving bins and pass into a rotating cylinder with grills used to separate the olives from any eventual residual soil, small stones, branches or any other foreign material. The leaves are sucked out with a vacuum and blown into a pile outside the mill.

After this the olives are transported by conveyor belt to a washing machine that gently cleans them with pre-filtered water.

Phase 2 - Crushing with Cutting Discs

The olives are crushed or ground up by metal rotating hammers. This method, as opposed to the traditional crushing or grinding with grindstones, prevents excessive disassembly of the vegetable cells and permits maximum conservation of the organalitic characteristics of the fruit. The velocity of the rotating hammers is regulated in such a way as to prevent any heating of the resulting olive paste. or pomace.

The machine used is stainless steel and has a propulsion of 25hp.

Phase 3 - Kneading or Granolatura

The pomace or oil paste obtained from crushing the olives is sent to the stainless steel modular vats which are self cleaning through use of a cover of warm circulating water. Inside the vat a rotating, helical spatula continuously mixes the pomace in order to allow for the separation of the emulsions that form during the crushing process.

This entire operation takes place at a low temperature (about 28°C) in order to fully preserve intact all the organoleptic characteristics of the oil. The first vats, hermetically closed, allow the process to be completed in a controlled atmosphere, which avoids any chance of contamination and/or oxidation.

Phase 4 - Decantation

Separation of the Oil from the Sansa by the “Decanter” Method

The Separation process takes place in a horizontal centrifuge using the “Decanter” method, allowing the separation of the solid mass or sansa from the liquid mass or oil and vegetation water .

The sansa, once separated, is eliminated from the production cycle and collected outside the mill, while the liquid mass is pumped on to the vertical centrifuge.

The “Decanter” is composed of a rotating stainless steel drum. It has “exits” whose levels may be regulated and controlled for the vegetation water and oil and also coded to transport the sansa outside the drum. The rotation has different speeds which are electronically controlled by electromagnetic brakes.

Phase 5 - Vertical Centrifuge Separation of the Water from the Oil

The last phase of the operation consists in transferring the liquid mass of oil and final vegetation water through a couple of vertical centrifuges, aligned in series allowing for the separation of the smallest traces of vegetation water from the oil. The vegetation water is pumped outside the mill and collected in a large vat and eventually used to irrigate /fertilize the surrounding fields.

The remaining Extra Virgin Olive Oil thus obtained is pumped into appropriate containers and consigned to the producer.

We take our Olive Oil directly back to Petroio and store it in Stainless steel tanks in our Olive Oil Room.

HARVEST:

The time when the olives are harvested depends on three elements: variety of Olive drupe or Cultivar, Altitude and Weather.

Cultivars: Frantoio, 60% Correggiolo 10% Moraiolo 10% Leccino 20%

Altitude: 360 s.l.m.

Weather: the olives are generally picked between the 15th of November and the 15th of December. When the invaiatura or the color of the olives changes from green to violet or brown it is time to get ready for the harvest.

The olives are hand picked by brucatura or browsing and pulled off the branch by a harvesting hand. They are stored in small plastic crates in a cool dry place and taken to the Frantoio or Olive Oil Mill within 3 days of harvest.

Olive Oil from Fattoria di Petroio is milled at the Frantoio di Pianella in Castelnuovo Berardenga Siena.

t comes exclusively from the 860 trees on the Property of Fattoria di Petroio, Quercegrossa, Siena

Frantoio di Pianella uses the Continous Cycle Method of Milling.

There are Five Cycles or Phases during the Milling Process

Phase 1

The olives are received and weighed.

Excess leaves are removed and the olives are lightly rinsed to take away any foreign, extraneous matter.

The olives are poured gently into receiving bins and pass into a rotating cylinder with grills used to separate the olives from any eventual residual soil, small stones, branches or any other foreign material. The leaves are sucked out with a vacuum and blown into a pile outside the mill.

After this the olives are transported by conveyor belt to a washing machine that gently cleans them with pre-filtered water.

Phase 2 - Crushing with Cutting Discs

The olives are crushed or ground up by metal rotating hammers. This method, as opposed to the traditional crushing or grinding with grindstones, prevents excessive disassembly of the vegetable cells and permits maximum conservation of the organalitic characteristics of the fruit. The velocity of the rotating hammers is regulated in such a way as to prevent any heating of the resulting olive paste. or pomace.

The machine used is stainless steel and has a propulsion of 25hp.

Phase 3 - Kneading or Granolatura

The pomace or oil paste obtained from crushing the olives is sent to the stainless steel modular vats which are self cleaning through use of a cover of warm circulating water. Inside the vat a rotating, helical spatula continuously mixes the pomace in order to allow for the separation of the emulsions that form during the crushing process.

This entire operation takes place at a low temperature (about 28°C) in order to fully preserve intact all the organoleptic characteristics of the oil. The first vats, hermetically closed, allow the process to be completed in a controlled atmosphere, which avoids any chance of contamination and/or oxidation.

Phase 4 - Decantation

Separation of the Oil from the Sansa by the “Decanter” Method

The Separation process takes place in a horizontal centrifuge using the “Decanter” method, allowing the separation of the solid mass or sansa from the liquid mass or oil and vegetation water .

The sansa, once separated, is eliminated from the production cycle and collected outside the mill, while the liquid mass is pumped on to the vertical centrifuge.

The “Decanter” is composed of a rotating stainless steel drum. It has “exits” whose levels may be regulated and controlled for the vegetation water and oil and also coded to transport the sansa outside the drum. The rotation has different speeds which are electronically controlled by electromagnetic brakes.

Phase 5 - Vertical Centrifuge Separation of the Water from the Oil

The last phase of the operation consists in transferring the liquid mass of oil and final vegetation water through a couple of vertical centrifuges, aligned in series allowing for the separation of the smallest traces of vegetation water from the oil. The vegetation water is pumped outside the mill and collected in a large vat and eventually used to irrigate /fertilize the surrounding fields.

The remaining Extra Virgin Olive Oil thus obtained is pumped into appropriate containers and consigned to the producer.

We take our Olive Oil directly back to Petroio and store it in Stainless steel tanks in our Olive Oil Room.